- More Details for Hot Forging?

- +86 13605779141

- sales@cxinforging.com

Hot Forging In Automobile Parts

Contact Info:

LongBanShan Industrial Park, YunFeng Street SuiChang, Lishui,China

86-577-86581226, 86581229.

Application Of Hot Forging In Automobile Parts

There is no doubt that the automobile or car industry is one of the fastest-growing industries today. So many people are working hard to own a car, and that’s the reason why the industry has been growing at a very fast rate. From this demand, manufacturers have been looking for ways to enhance the production of automobile parts. One of the technologies being widely used is hot forging.

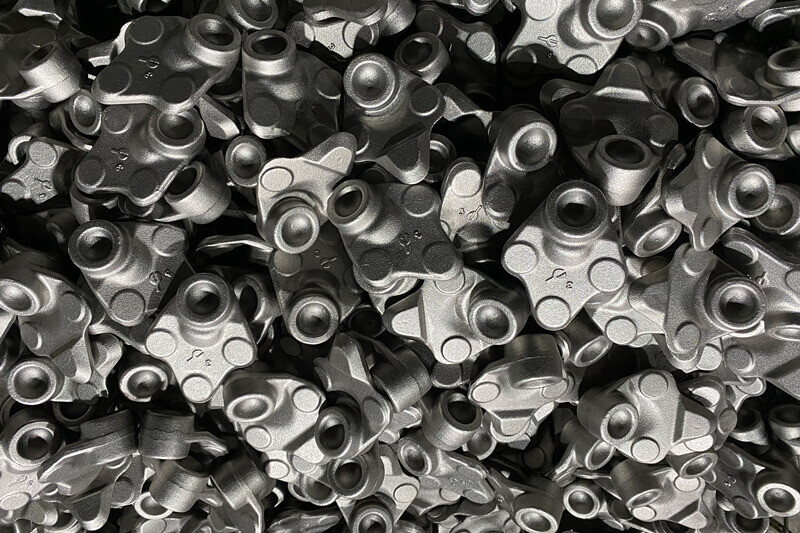

Hot forging, also referred to as hot extrusion, is mainly used in the manufacturing of automobile parts. The technology is pretty versatile in production in that it can be used for the production of a vast range of parts. In fact, almost all automobile parts can be made using this technology. This includes the gears, bearing, chassis parts, brake parts, frame parts, clamp parts, crankshafts, pedal parts, and the kick-starters. Other automobile parts manufactured using hot forging includes cranksets, connecting rods, camshafts, slack adjusters, shift forks, and many more.

The application of hot forging forming technology is pretty simple. As the name suggests, the technology works on heated workpieces. The metal to be formed must be heated first to the crystallization temperature to reach plastic deformation. This makes it easy to turn it into the desired shapes. The workpiece’s heating also helps lower the stress and press force required for the parts’ formation.

But to work with the hot forging technique, you need to invest in hot forging forming machine. Fortunately, there are all kinds of forming machines to select from. But the Friction press for hot forging are the most recommended. These machines use hydraulic pressure and specially design moulds to form the desired automobile parts.

How To Hot Forge Automobile Parts Works

The application of hot forging in the manufacturing of automobile parts is pretty simple. In fact, it’s this simplicity that most automobile manufacturers are using it. The process of producing parts using this forming process is not as complicated as it sounds. There are several things that you need to get right for the process to work efficiently.

First, the material to be formed must be heated to crystallization temperature. This will make it very easy to form the metal to the required shape and size. Make sure that the die is of the right size. The other thing that you need to consider is the force needed to form the automobile parts. Now you can start the manufacturing process.

Place the mould in the press chamber and add the metal to be formed on top of it. Then place a punch on the material to press it. That’s simply how you hot forged the automobile parts. Make sure that the pressing force is accurate because it is a very crucial factor.

Advantages of Hot Forging

There are many reasons for hot forging automobile parts. There are also many advantages that come with using forged machine parts. One of the advantages is the increased ductility. Unlike the cold forged parts, these parts offer better ductility, which offers better material deformation. Therefore, the material can withstand high stress and offer many configurations.

Hot forging requires less energy to form machine parts. Because the material is heated to reach plastic deformation, less force is needed to form the required shapes. The other benefit is more flexibility in production. Unlike cold forging, you can make many more customized parts with hot forging.

The other benefit of hot forging is excellent surface quality. The technique produces a porosity free surface, which allows a range of finishing work. You can polish, painting, or coating to customized specific needs. These are just some of the advantages.

At Hot Forging China, we use hot forging or impact extrusion to produce highly complex hot forged automobile parts. Mechanical finish, annealing, and surface coating complete our service range.

We offer a range of hot forged automobile parts and other machine parts. We will work closely with you to develop the desired parts. If you are interested in hot extrusion or hot forging and need a free quotation, please contact us. We will provide you with a series of hot forging solutions. We can also do mass-production for bulk orders.